- HOME>

- Water Supply & Drainage Division>

- Biofilm Method Wastewater Treatment Equipment: AQUACUBE

Water Supply & Drainage Division

Products Introduction

Microorganism fixing carrier for fluidized bed

“AQUACUBE” has the unique durability of polyolefin material as well as fine fluidity/microorganism adhesion. This microorganism fixing carrier lowers maintenance costs and running costs at a wastewater treatment facility and comes in a space saving design. It has many advantages, including microorganisms at high concentration, high water resistance, durability, and excellent performance shortly after installation.

Principles of AQUACUBE

The bio carrier method using AQUACUBE is a wastewater treatment system where pollutants in wastewater are removed by aerobic microorganisms attached to the carrier (AQUACUBE) in an aeration tank.

In the aeration tank, aeration is performed by a blower and oxygen is supplied to microorganisms attached to the carrier. At the same time, carrier flow is created in order to provide contact between the wastewater and carrier for effective treatment.

As the aerobic microorganisms treat the wastewater in the carrier, increase by propagation and decrease by self-digestion occur, adjusting to the amount of sludge retained in the carrier optimum according to the conditions of wastewater treatment. Also, parts of the sludge detach from the carrier and flow out as SS.

Features

-

- 1.A high concentration of bacteria can be maintained due to the large surface area.

-

Values are representative Material Polyolefin Dimension 10x10x10mm(cube) Voidage ratio 96% Cell diameter 1.1mm Specific surface area 3000m2/m3 Actual gravity 0.99g/cm3 Bacteria adherence amount is 30 - 50g per 1Lcarrier. Wastewater is treated at equivalent high Activated Sludge concentrations of 6,000- 10,000mg/L (at 20% filled carrier). Moreover, aerobic conditions are maintained inside the highly permeable carrier due to the unique and continuous cell structure, resulting in treatment efficiency.

-

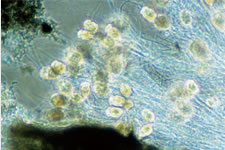

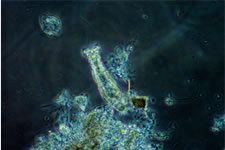

- Photograph of the AQUACUBE under the microscope.

Unique continuous forming structure encourages the high retention of bacteria.

- Cut piece of

AQUACUBE

-

- Bacteria inside a AQUACUBE (100x magnification)

-

- 2.Long Life, Superior water resistance.

-

- AQUACUBE

- Before testing→

140 days later (97.6%)

- Urethane carrier

- Before testing→

140 days later (40.0%)

As the carrier deteriorates, the captured volume of microorganisms drops and processing efficiency decreases. Therefore AQUACUBE made from a polyolefin material with exceptional water resistant properties. Please refer to our test results below. Shape is retained even after use for over one year. Running costs are reduced by filling the carrier.

- AQUACUBE

-

Reduction ratio

after 4 years is less than 5%,

no refill required.- water tank (concrete):

- inner dimensions 200x200x300mm

- carrier:

- 15vol%

- agitation:

- single stage blades 300rpm

-

- 3.Due to excellent permeation property and fluidity, efficiency can be achieved shortly after filling.

-

The AQUACUBE is comprised of Polyolefin material with improved hydrophilic properties, and becomes rapidly immersed. Bacterial attachment is quick and efficiency can be seen in a short period of time. Also, even after the bacteria is attached, gravity remains close to the water (1.05g/cm3), aeration volume does not increase and operating costs are low.

Unavoidable Problems with the “Activated Sludge System”

-

- “Operation Management is time and labor expensive”

- Management of operations of the activated sludge method requires time and effort. Professional knowledge is necessary in order to obtain stable water quality.

-

- “Treatment costs for Excess Sludge is expensive”

- In the activated sludge process, a large volume of sludge is produced. Resulting costs in order to treat the excess sludge and to maintain devices are expensive.

-

- “Small Treatment Capacity”

- In order to handle fluctuations in wastewater, such as an increase in wastewater volume and changes in wastewater, an existing wastewater treatment facility must often be expanded.

-

- “A wastewater treatment facility requires a Large Area”

- A major disadvantage to the activated sludge system is that a large area is required for the treatment facility. If sewage discharge is possible, the advantage of the activated sludge system is small.