- HOME>

- Water Supply & Drainage Division>

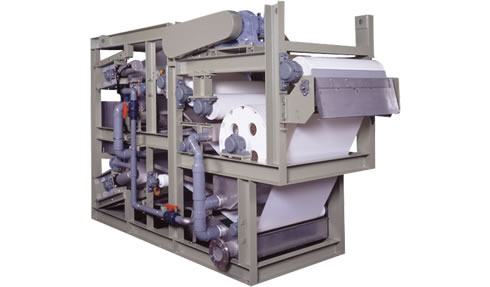

- L type Dehydrator

Water Supply & Drainage Division

Structure and Flow

Products Introduction

Floc formed in the coagulant reactor tanks passes through the charge box and is uniformly supplied to the lower filter cloth. After passing through the gradual pressure roller (slotted roller) while being squeezed between the special filter cloth, the sludge is dehydrated by the shearing dehydration section consist of sequentially small diameter rollers and is discharged as cake.

Features

-

- 1. Broad versatility

- Double Coagulant Reactor Tanks are equipped as standard accessory.

-

- 2. Recycler (option)

- Greatly reduces washing water (reduction of 50% to 80% possible depending on the sludge)

Main Body Specifications

| (Treatment Capacity in case of Pressure Floatation + combined excess sludge) | ||||||

| Type | L-03 | L-05 | L-10 | L-15 | L-20 | |

|---|---|---|---|---|---|---|

| Treatment Capacity (kg・DS/h) |

10~25 | 30~45 | 60~90 | 90~130 | 120~180 | |

| Effective Filter Cloth Width (mm) |

300 | 500 | 1,000 | 1,500 | 2,000 | |

| Washing Water Volume (m3/h) |

1.9 | 2.6 | 4.6 | 6.7 | 8.6 | |

| Motor (kW) |

0.80 | 1.20 | 1.20 | 1.95 | 2.30 | |

| Outer Dimension (mm) |

Length | 2,400 | 3,150 | 3,150 | 3,500 | 3,500 |

| Width | 1,220 | 1,450 | 1,950 | 2,500 | 3,000 | |

| Height | 1,620 | 2,000 | 2,000 | 2,200 | 2,200 | |

| Weight (kg) |

1,100 | 1,900 | 3,000 | 4,500 | 5,600 | |