- HOME>

- Water Supply & Drainage Division>

- MMD vs. SMC

Water Supply & Drainage Division

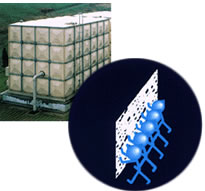

There are two methods of manufacture in the panel tank industry, the MMD (Matched Metal Die) method and the SMC (Sheet Mould Compound) method. The MMD method is Sekisui's own exclusive design and continues to be the most effective method for manufacturing tank panels today. All other tank manufacturers use the SMC method. The MMD method uses long continuous filament of glassfibre in a mat form, adding resin and then submitting the mixture for the final moulding process. In retrospect, the SMC uses short, chopped strands of glassfibre and resin in a "clay-like" mixture.

Each of the long glass fibres used in Sekisui tank panels are woven together in the form of a mat. Further, each individual fibre strand is made by weaving together even finer strands in much the same way a rope is made.

The Different Glassfibre Used In Panel Tanks

- MMD

- SMC

The Following Is A Simplified Explanation Of Our MMD System:

- First, the glassfibre sheets are constructed: Thin threads of glassfibre are tied together and are then woven into a net-like formation. The sheet in its final form is much like a piece of cloth.

- These fibre sheets are then stacked on top of each other. The number of sheets used depends on the type of panel to be constructed and the desired strength.

- The resin and other chemicals are applied and then pressed together to form the specified panel.

The Advantages Of The Sekisui

MMD Panel Manufacturing Method

- MMD Method

- Uses long continuous filament fibre for extremely high strength!

- Panel UsesHighly suitable for high water pressure!

Highly suitable for water storage.

- SMC Method

- Uses short-strand fibre which gives rise to questions regarding strength!

- Suitable

for low water pressure applications!Suitable for bathtubs (depth of 0.3m - 0.5m) and other items that only need to bear the weight of a single individual, such as chairs and the like.

Comparison Specifications

| Tensile Strength | |

|---|---|

| Note: Sekisui tanks attain Singapore Standard "SS245" at 6 times working pressure under hydrostatic pressure tests. | |

| MMD Sekisui | 85 - 105MPa |

| SMC Company A | 58.8 - 100MPa |

| Hand Layup Company B | 39.2 - 68.6MPa |